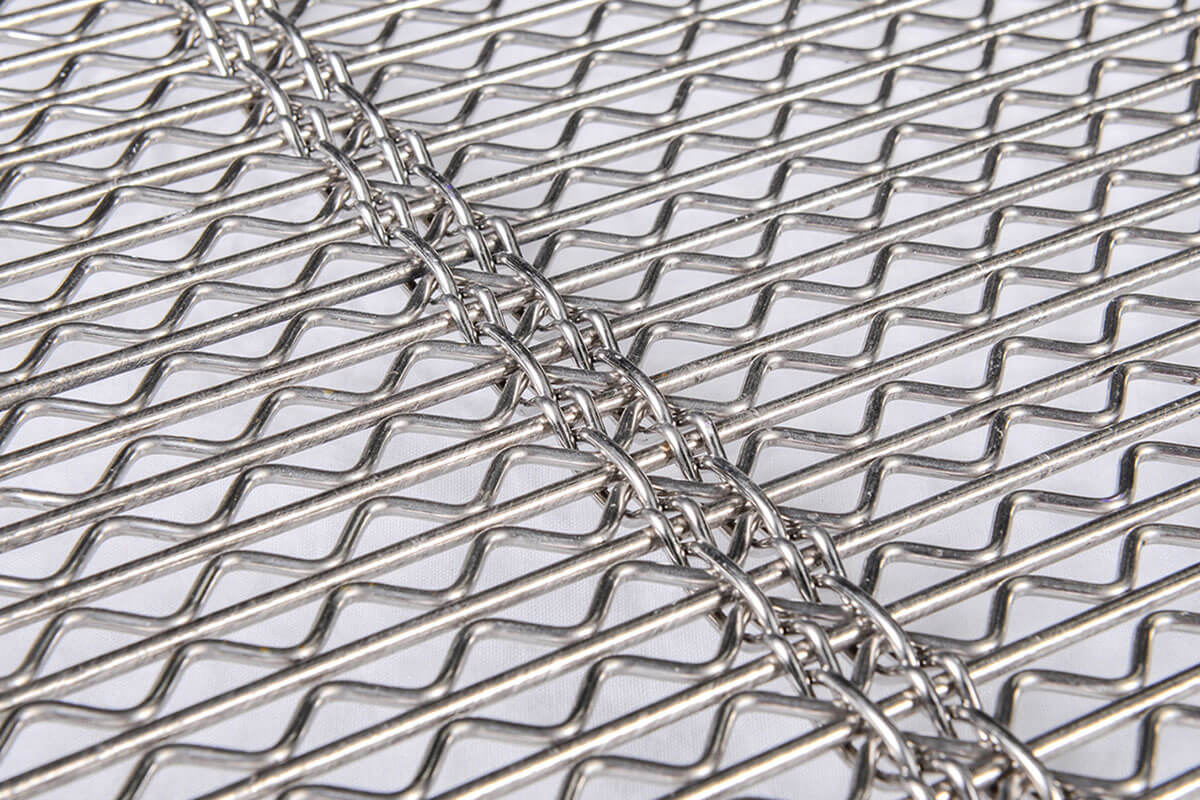

Triangle pattern self-cleaning screen

The triangular self-cleaning wire screen is specially designed to reduce blindness and blockage when the conventional square opening mesh cloth cannot be acceptable. The triangular self-cleaning wire screen is composed of straight metal wire and wavy metal wires. It is similar to the square self-cleaning screen. However, unlike the square self-cleaning screen, a straight metal wire is added between the wavy metal wires to support and improve its screening accuracy. The diameter of the straight wire is slightly larger than it of the wavy wire. The crimped wire can determine the size of the hole. Both straight and crimped wire is alternately woven with the tie wires on the longitudinal support rods. The longitudinal support rods are also called crossbands, which are made of woven metal wire or polyurethane. But polyurethane is not suitable for use in hot-mixed batch asphalt plant.

This self-cleaning screen has a high ability to withstand heavy loads (due to the addition of straight steel wire as support), and a good self-cleaning effect obtained by the natural vibration of the wave wires.

This screen effectively reduces blindness and blockage while maintaining self-cleaning.

Features

- Can be made of carbon steel and stainless steel

- There are polyurethane cross band and steel wire cross band available.

- A high ability to withstand heavy loads

Request a quote